The access to clean drinking water is a necessity for every human on this planet. Developing better piping and infrastructure has been a large initiative in East and Central Africa. The key for every system is to ensure that we are preparing sustainable solutions that will impact our future generations. HDPE piping system has been the system of choice for engineers around the world and in East Africa.

HDPE Technology has replaced several conventional material including PVC, iron, copper and concrete. It is the material of choice among engineers, contractors and customers for a wide variety of industry applications including municipal, industrial, energy, geothermal, mining, gas, oil, mining and agricultural application, for sewer, water and telecommunications. Utility infrastructures rely on the quality of piping for efficiency and effective delivery

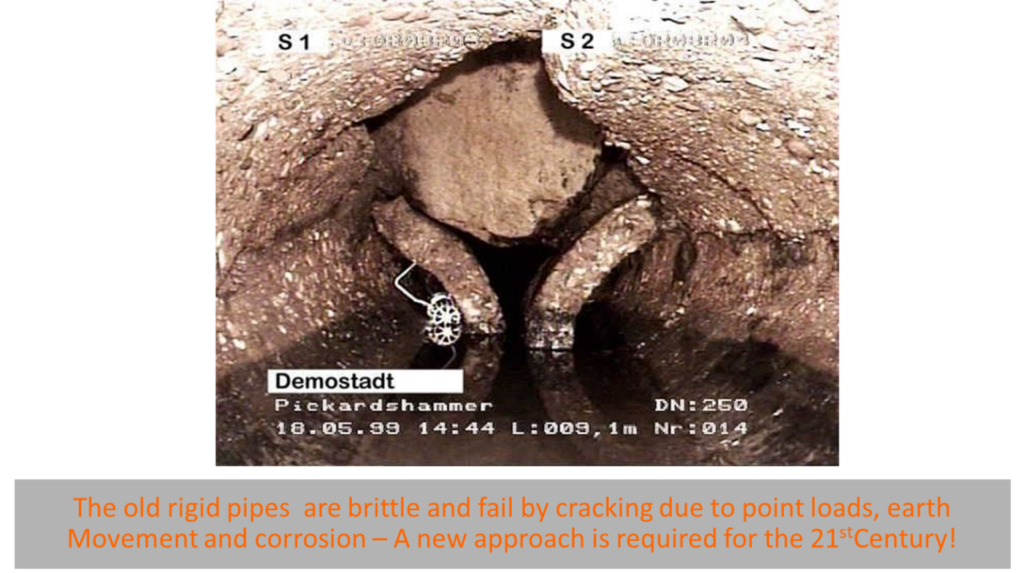

UPVC can be brittle while Steel pipes are affected by chemicals and rough material causing them to rust.

TECHNICAL AND COMMERCIAL ADVANTAGES

High-density polyethylene (HDPE) pipes are highly recommended in these projects compared to the alternative pipes due to the below features:

- Technically superior

- Higher corrosion and abrasion resistance

- Improved hydraulics

- Ability to deflect load, and transfer this to the surrounding soil, resulting in higher loading capability as a system than alternatives.

- Longer lifetime

- Built to last for over 50 years

- Resilient and durable system, with high chemical resistance and impact

- Fully recyclable

- Economically superior

- Better value than the alternative – cost effective to install

- Easier to install – robust jointing techniques, lighter, stronger and flexible

- Environmentally sustainable footprint because it is non-toxic

AQUAFLEX – STANDARD BEARER OF QUALITY IN EAST AFRICA

Aquaflex (manufactured by Danco) are the standard bearer for manufacturing quality pipes through their processes and keeping quality at the forefront of everything they do. The most important is the use of 100% PE100 certified virgin raw material. This is key for them to keep to the international standard. In addition, it is keeping to the correct wall thickness to achieve the pressure needed for each pipe and finally the rigorous laboratory testing that is performed on all pipes made.

MARAGWA WATER SUPPLY – HDPE IN ACTION

Looking at the just completed project that was supplied with HDPE pipes 630MM, Maragwa Water Supply Project – The dam is the second largest water reservoir to be constructed in the county after Ndakaini holding 60 million cubic litres of water. The dam is currently serving about 170, 000 homesteads in the lower Murang’a for both domestic and irrigation purposes.

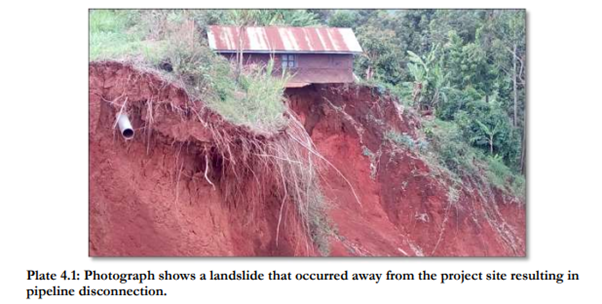

For Maragwa the choice of using HDPE pipes is a success story as the pipe can also take pressure and movement that will potentially destroy other conventional rigid pipe. The high-density plastic HDPE is ideal for these applications, as it is very durable and flexible it is also well suited to installation in dynamic soils including in earthquake and landslide -prone areas. It can also be bent on site to a radius twenty-five times the nominal pipe diameter – for SDR11 and SDR17 pipe. This provided a major cost savings compared to the different pipe systems, some of which require glued fittings, restraints or thrust blocks for even minor changes in direction.

See below an image showing a previous pipeline breakdown after a landslide in Muranga.

Image source: Water Fund report

Maragwa pipeline with Aquaflex HDPE Danco pipes showing the flexibility nature of the pipes

KERICHO WATER SUPPLY – STEEL REPLACED BY HDPE

Another of a similar success story is the Kericho project. The contractors were tasked with creating new water treatment for distribution to connect and supplement the existing pipelines because the population and consequently the demand for water had increased.

The complete project is going to serve over 70,000 households in Kericho for the next 12 years when the demand increases again.

As per an interview with the project consultant, Eng. Dinesh Hirani, the Technical Director, Mangat I.B. Patel (MIBP) Ltd, he mentioned that their initial design was to initially use Steel, but the engineers changed their designs along the way considering the great features that HDPE have, including manufacturing timelines of the pipe compared to Steel. Some of the major features that stood out for them to use HDPE pipes include the lightness of the material as compared to steel. This therefore meant a huge cost savings on transport and movement of the pipe to the inside of the trench. They also considered the ease in jointing of the HDPE pipes which is easier to use its fittings, making it easier to navigate most of the bends with no joints due to its flexibility features, this therefore ensure minimal or no weakness points. It is equally the best when it comes to welding as it fuses easily and gives a perfect strong joint as compared to steel cement lined pipes, whose inner lining can easily detach and damage the joint during welding. Compared to steel, HDPE does not rust and even with objects like stones, it is not easily scratched on the surface as it only thins away.

Eng. Dinesh reiterated that all engineers are now choosing HDPE as a preference as it would be the new piping system compared to UPVC and steel. He continues to encourage all water companies to choose HDPE for their piping systems. But he added that in as much as this material is the best yet, it will be important to source the high-quality pipes from reputable manufacturers to ensure the clients enjoy the full benefits of a good piping system.

Kericho site with 630MM Aquaflex HDPE Danco pipes

Site visit with the contractors and our onsite engineers to ensure we walk the journey with our customers.

On site jointing and welding of HDPE pipes with hurner welding machine.

Indeed HDPE pipes are the best choice for a long lasting impact. However, for guaranteed benefits that high-quality HDPE pipes provides, it is even more important to only opt to purchase these pipes from a highly reputable manufacturing company that has years of experience. We welcome all stakeholders to move with Danco to improve lives for the next generation.

For further technical information and more detailed information on the advantages of DWC please visit the Danco website www.dancoplastics.com or contact the team on info@dancocapital.co.ke